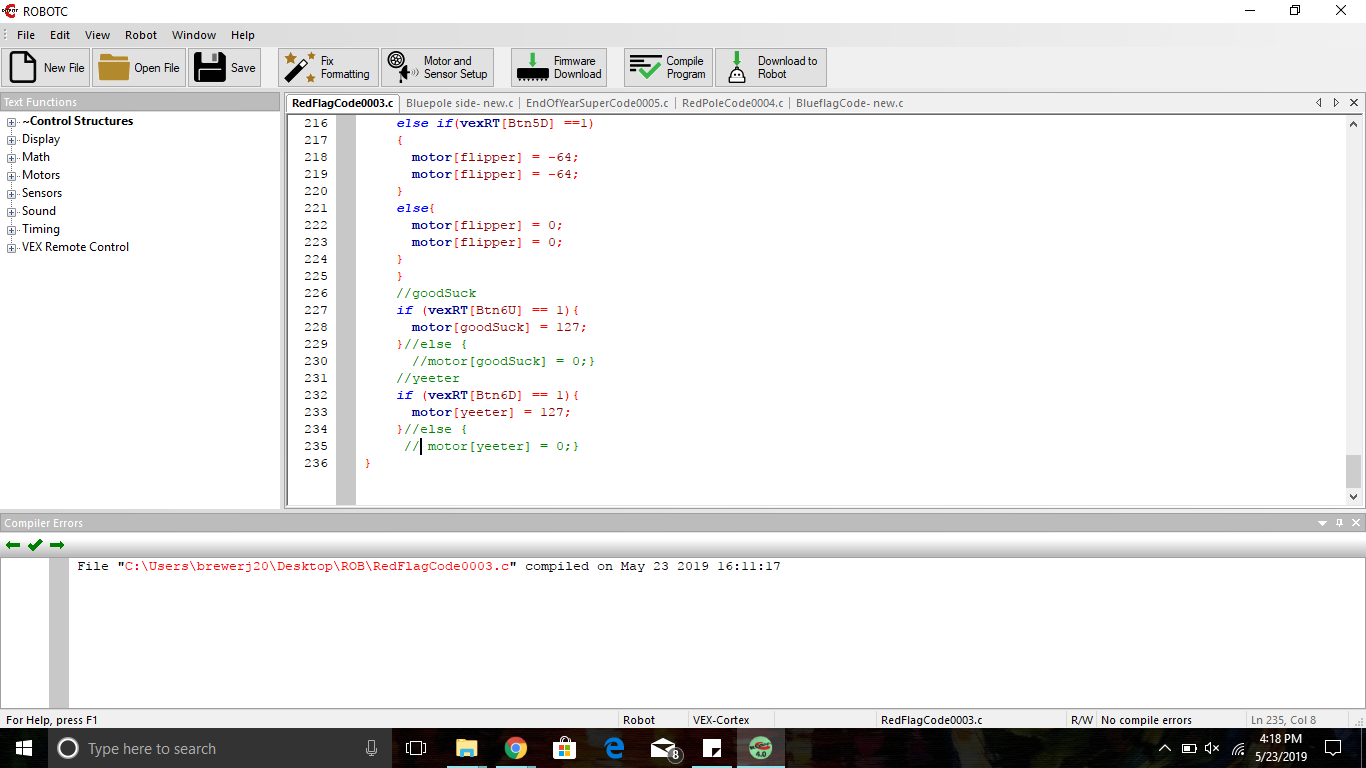

6 deg/min even with the jitter range that RobotC claims to use. Recent testing of programming robot have shown drift rates of. My 3.58 RobotC now shows the dead zone at 4 counts now or 2.8 deg/sec. Ok.so it looks like the 3.08 RobotC dead zone is +-3 counts…. Suppose gyro bias in 1840 they the ‘ignore jitter’ would treat values in 1837 to 1843 as if they were the steady state value.” Introduce a “gyro jitter range” setting that ignores very small changes for gyro steady state position. Fix some small bugs in gyro bias calculation. Change bias setting for gyro from 130 to 131. Make “nGyroJitterRange” and “bHasSensorBiasSettings” #define parameters in “loadBuildOptions.h”. Without this deadzone you would expect to see a random walk drift on the integration of the gyro angle when sitting still. This is less than 1 count on the A/D output so the dz should be placed at 1 counts to keep the gyro integration from drifting. Typically we set the deadzone at the 2 sigma level of the total noise sources or. The standard deviation of the sampling noise is typically about. The A/D sampling resolution is 1 bit from above is. 016 deg/s/√(HZ) and the bandwidth is 140 hz so the noise output =. The cortex equation that converts A2D to dps can be derived as follows: Don’t know why they didn’t amplify it to 5v … but it results in a gyro scale factor of 600 deg/s/volt. The Vex people amplified the output by a factor of 1.511 so that the nominal 3 V max is 4.533 v. The gyro chip is a MEMS ST LY3100ALH 1000 deg/sec max rate gyro. I bought a Vex Gyro at Worlds and decided to try it out with RobotC. In this video Jim shows you how.Revised based upon more accurate information for Vex people. 8 Using IF Structures– to make a micro-controller complete complex tasks, IF statements can be the go-to to make it easier.7 Functions & Voids– What are functions and voids, and how can they make it easier to program your VEX hardware? Here’s the video for you….6 Variables– Believe it or not EVERY programming language uses variables, and there are many good reasons to.Want to perform a complex task with your VEX hardware? Chances are you’ll need a While Structure to do it.

#Vex robotc how to

4 Looping With Natural Language– Learn how to do things multiple times using Natural Language… the “easy” way.3 Adding an Input Using a Limit Switch– It’s amazing what you cn do with a switch and a microcontroller when you really think about it!.2 Uploading a Program to a VEX Cortex– Pretty easy, but without this step, nothing works!.

#Vex robotc software

#Vex robotc series

In this series of short videos, learn the basics of how to use RobotC to program a VEX micro-controller to control all of your VEX creations from robots to control systems. In industry they use PLC’s, in the classroom we use arduino and VEX components. Mind boggling! It’s all done with some form of logic controller.

Think about all of the systems that have to be controlled in a single work cell in a factory… then multiply it by 10’s or 100’s of cells. When you think about it, in manufacturing, controlling things is necessary to perform very complex tasks to manufacture items to tolerances finer than a human hair.

0 kommentar(er)

0 kommentar(er)